| Unit Price: | USD 0.5000 / Kilogram |

|---|---|

| Min. Order: | 5000 Kilogram |

Basic Info

Model No.: 1/8"-4"

warranty period: 3 years

Certification: CSA, pcoc, Reach, IECEE, scoc, UL, EPA, GS

Support customization: OEM, ODM

place of origin: China

Craft: Forged

Connection method: Welding

shape: Equal, Reducing

Additional Info

Packaging: wooden case

Productivity: 500000ton/yaer

Brand: GH

Transportation: Ocean,Land,Air

Place of Origin: CN

Supply Ability: 500000

Certificate: CE/PED 2014/68/EU ,AD2000W0 ASME PP&U

HS Code: 7307910000 /7307210000

Port: Tianjin,Shanghai,Qingdao

Product Description

PRODUCT DESCRIPTION

|

ASTM A182 /ASME SA182 |

Standard Specification for Forged or Rolled Alloy-Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service | ||||

| Low alloy Steels | F1 | F2 | F5, F5a | F5 | F91 |

| F92 | F911 | F11, | F12 | F36 | |

| F21, F3V, F3VCb | F22, 1/3/V | F23 | F24 | FR | |

| F122 | F10 | F9 | |||

|

Martensitic and Ferritic Stainless steel |

F6a | F6b | F6NM | F XM-27Cb | F429 |

| F430 | |||||

| Austenitic Stainless steel | F304 | F304H | F304L | F304N | F304LN |

| F309H | F310 | F310H | F310MoLN | F316 | |

| F316H | F316L | F316N | F316LN | F316Ti | |

| F317 | S31727 | S32503 | F321 | F321H | |

| F347 | F347H | F347LN | F348 | F348H | |

| FXM-11 | FXM-19 | F20 | F44 | F45 | |

| F46 | F47 | F48 | F49 | F56 | |

| F58 | F62 | F63 | F64 | F904L | |

| Ferritic-Austenitic Stainless steel | F 50 | F 51 | F 52 | F 53 | F 54 |

| F 55 | F 56 | F 57 | F 58 | F 59 | |

| F60 | F61 | F65 | F65 | F67 | |

| Product Form | |||||

|

Flanges(ASME B16.47,B16.48 ,B16.5,MSS SP44,BS10,BS3293 ,BS4504,ISO7005-1) |

WN(welding-neck);SO(slip-on);PL(Plate);BL(Blind);Th(Threaded);SW(scket-welding);LF/SE(lapped flange/stub end);LWN(long welding neck);Orifice flange;Reducing flange; API flange;Integral/Compact flange;Spectacle blind,Lind spade and spacer,Paddle blind,Paddle spacer; Orifice plate;Pipe plate,Bleed ring,Overlap Flange. |

||||

| ASME B16.11 | Forged threaded fittings:90-deg elbow,45-deg elbow,tee,cross,coupling,half-coupling,cap,square head plug,hex head plug,round head plug,hex head bushing,flush bushing,street elbows | ||||

| ASME B16.11 | Fogred socket weld fittings:90-deg elbow,45-deg elbow,tee,cross,coupling,half-coupling,cap | ||||

| MSS SP83 | Steel Pipe Unions(socket welding and threaded end) | ||||

| MSS SP95 | swage nipples,bull plug(ends may be threaded,beveled,plain) | ||||

| MSS SP79 | socket welding reducer inserts | ||||

| MSS SP97 | weldolets,threadolets,sockolets,flangolets,elbolet,sweepolets,saddle,nipolets,brazolets,latrolets,insertolets | ||||

| Forgings | Forgings,Rings,Discs,Disks,Tubesheets,Shaft,Sleeves,Bars,Valves,etc. | ||||

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Size | 1/2″NB TO 4″NB IN |

| Class | 3000 LBS, 6000 LBS, 9000 LBS |

| Value Added Services: | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

| Production Grades: | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

| Stainless Steel | ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L |

| Duplex & Super Duplex Steel | ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950. |

| Carbon Steel | ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C |

| Alloy Steel | ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91 |

| Copper Alloy Steel | ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30) |

| Nickel Alloy Steel | ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276) |

|

|

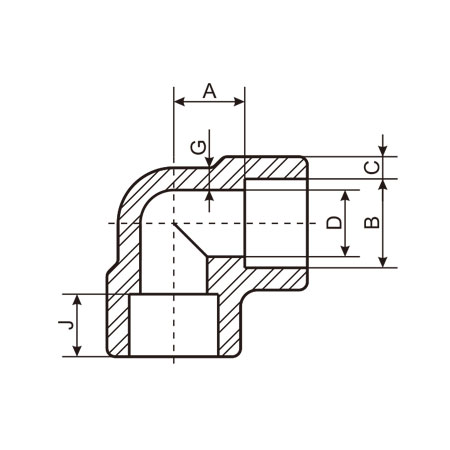

| DN |

Nom. Pipe Size |

Center to Bottom of Socket-A |

Socket Bore Dia. B |

Bore Dia.Of Fitting D |

Socket Wall Thickness(2) C |

Body Wall Thickness G |

Depth of Socket Min. J |

||||||||||||||

|

90°Elbows Tees,Crosses |

45°Elbows | Class Designation | Class Designation | ||||||||||||||||||

| Class Designation | Class Designation | Class Designation | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | |||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | Ave. | Min. | Ave. | Min. | Ave. | Min. | Min. | Min. | Min. | ||||

| 6 | 1/8" | 11.0 | 11.0 | --- | 8.0 | 8.0 | --- | 10.8 | 6.9 | 4.0 | --- | 3.18 | 3.18 | 3.96 | 3.43 | --- | --- | 2.41 | 3.15 | --- | 9.5 |

| 8 | 1/4" | 11.0 | 13.5 | --- | 8.0 | 8.0 | --- | 14.2 | 9.3 | 6.4 | --- | 3.78 | 3.30 | 4.60 | 4.01 | --- | --- | 3.02 | 3.68 | --- | 9.5 |

| 10 | 3/8" | 13.5 | 15.5 | --- | 8.0 | 11.0 | --- | 17.6 | 12.6 | 9.2 | --- | 4.01 | 3.50 | 5.03 | 4.37 | --- | --- | 3.20 | 4.01 | --- | 9.5 |

| 15 | 1/2" | 15.5 | 19.0 | 25.5 | 11.0 | 12.5 | 15.5 | 21.8 | 15.8 | 11.8 | 6.4 | 4.67 | 4.09 | 5.97 | 5.18 | 9.35 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 |

| 20 | 3/4" | 19.0 | 22.5 | 28.5 | 13.0 | 14.0 | 19.0 | 27.2 | 21.0 | 15.6 | 11.1 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 |

| 25 | 1" | 22.5 | 27.0 | 32.0 | 14.0 | 17.5 | 20.5 | 33.9 | 26.7 | 20.7 | 15.2 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 |

| 32 | 1-1/4" | 27.0 | 32.0 | 35.0 | 17.5 | 20.5 | 22.5 | 42.7 | 35.1 | 29.5 | 22.8 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.70 | 12.5 |

| 40 | 1-1/2" | 32.0 | 38.0 | 38.0 | 20.5 | 25.5 | 25.5 | 48.8 | 40.9 | 34.0 | 28.0 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 |

| 50 | 2" | 38.0 | 41.0 | 54.0 | 25.5 | 28.5 | 28.5 | 61.2 | 52.5 | 42.9 | 38.2 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16.0 |

| 65 | 2-1/2" | 41.0 | --- | --- | 28.5 | --- | --- | 73.9 | 62.7 | --- | --- | 8.76 | 7.67 | --- | --- | --- | --- | 7.01 | --- | --- | 16.0 |

| 80 | 3" | 57.0 | --- | --- | 32.0 | --- | --- | 89.8 | 78.0 | --- | --- | 9.52 | 8.30 | --- | --- | --- | --- | 7.62 | --- | --- | 16.0 |

| 100 | 4" | 66.5 | --- | --- | 41.0 | --- | --- | 115.2 | 102.3 | --- | --- | 10.69 | 9.35 | --- | --- | --- | --- | 8.56 | --- | --- |

16.0 |

| Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. |

© 2021 All Rights Reserved.HeBei GuangHao Pipe Fittings Co .,LTD,Inc. All Rights Reserved. Sitemap. Sitemap.html